Safety

Safety Commitments and Goals

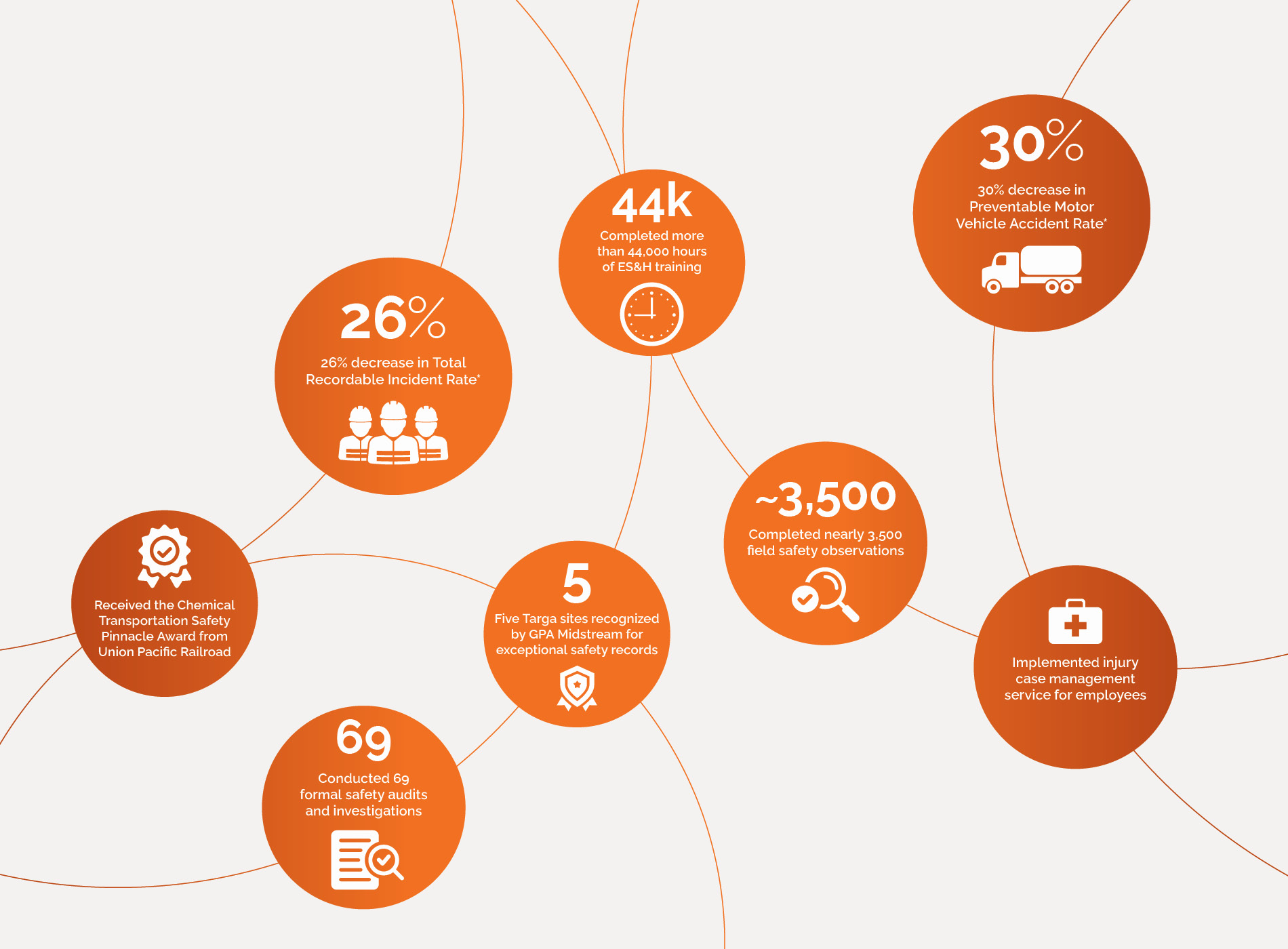

We prioritize safety everywhere in our organization. Investing in safety programs that protect our employees and communities strengthens our company and is aligned with our core values. We believe that “Zero is Achievable,” and our goal is to operate and deliver our products without any injuries.

Safety Training

Our safety training program is designed to actively engage employees and contractors in all aspects of safety, and to provide the knowledge and skills needed to operate safely and responsibly. It includes a dynamic combination of online and instructor-led training and is conducted at least annually for field employees.

Emergency Preparedness and Response

As a responsible member of the communities where we operate, we have robust processes in place to prepare for and appropriately respond to a wide range of emergencies.

Emergency Response Program

Our Corporate Crisis Management Plan is designed to cover any emergency event that may occur. It adheres to the guidelines stipulated in our ES&H Policy, and the Executive team oversees its implementation.

Emergency Response Drills and Outreach

We recognize that our emergency response plans are most effective when coupled with regular, comprehensive training and drills. In 2022, we conducted 12 pipeline emergency response drills, including five deployment exercises and seven tabletop drills. Approximately 17 different local first responder agencies, eight different local emergency management committees, and numerous state and federal agencies participated in the drills.