Environmental Management

We use a system of management policies, work practices, and controls, including automated permit compliance tracking, facility monitoring and reporting programs, compliance audits, and training. Our corporate environmental subject matter experts keep these policies and practices up to date, while our field environmental specialists work with other functional groups across Targa, including engineering, construction, and operations, to oversee their implementation.

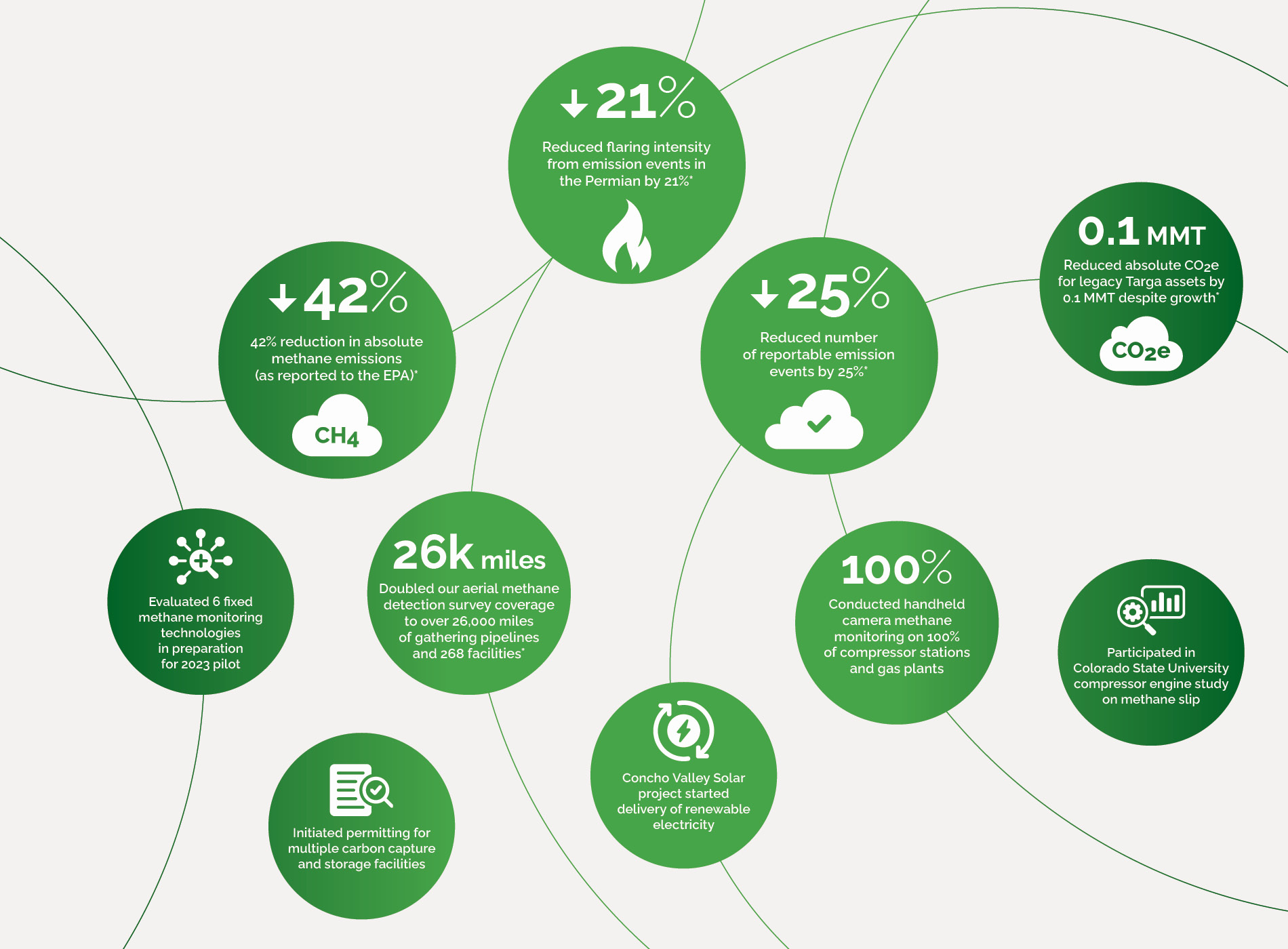

Methane Management Plan

We have long been committed to industry collaboration and innovative solutions to reduce methane loss. These collaborative and sustained efforts have informed our methane management plan, which centers around the utilization of various detection technologies to effectively identify methane leaks and the continued implementation of robust maintenance and equipment reliability programs.

Our Approach to Reducing Flared Volumes

As a responsible operator, we take a proactive approach to mitigating flaring incidents. Through a combination of strategic planning, collaboration, strong asset integrity and maintenance programs, and effective combustion techniques, we aim to reduce flared volumes while maintaining the safety and integrity of our operations. Flaring, when it occurs, is predominantly for safety reasons such as relieving pressure during unplanned events such as third-party outages, weather, unplanned maintenance, or other unexpected operational upsets.